There are two common types of wind-induced vibration observed in poles…First Mode Vibration and Second Mode Vibration.

First Mode Vibration

In first mode vibration, sometimes referred to as sway, the maximum deflection occurs at the top of the pole. First mode oscillation typically occurs at a low frequency of approximately one cycle per second. Normal deflection of this shape usually is not harmful to the pole or luminaire, but first mode oscillating vibration will cause damage and failure.

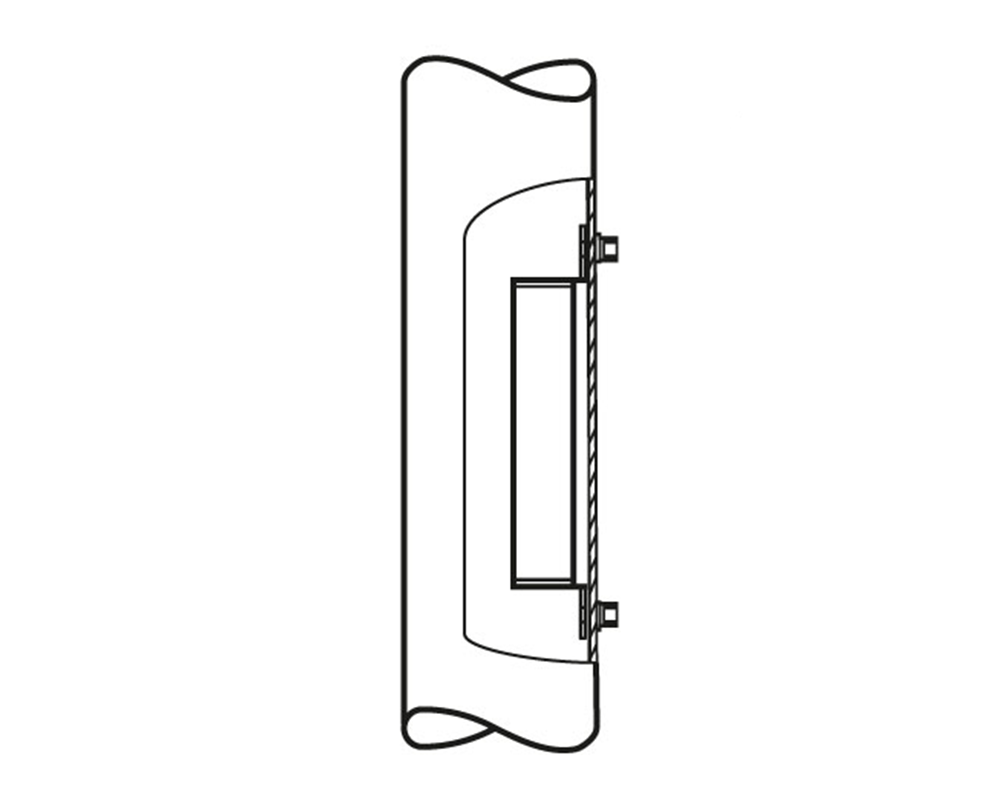

Second Mode Vibration

Second mode vibration can be the most damaging form of vibration. It occurs approximately at the midpoint of the pole with the deflection off center equal from side-to-side. It occurs at a higher frequency, typically three to six cycles per second. Second mode vibration occurs when the wind synchronizes with the pole’s natural frequency of vibration. This is known as resonance. As the steady low level wind moves past the pole, vortices are shed alternately from either side of the structural shaft causing displacement oscillations in a direction perpendicular to that of the wind.

Wind induced vibration can be caused by steady, relatively low-speed wind (10-30 mph), by topography and by the structure to which the pole is mounted or nearby structures. Destructive vibration is not an indication of substandard material, workmanship or design of pole.