Thermoset Powder Coat Finishes – Aluminum

Hapco’s on-site, state-of-the-art powder coating operations utilize weather resistant triglycidyl isocyanurate (TGIC) polyester thermoset powders that are electrostatically applied, oven cured and bonded to a minimum dry film thickness of 2.0 mils. The National Association of Architectural Metal Manufacturers, Metal Finishes Manual, rate the outdoor life of these powders at 15 plus years.

AAMA 2604

All polyester thermoset powders are not created equal. The American Architectural Manufacturers Association (AAMA) provides classifications for powder coatings which are industry recognized standards for testing and performance. AAMA 2604 coatings, known as Super Durable, are formulated with advanced polyester resin technology that utilizes higher performance pigments. Qualities include superior gloss, color retention and weathering capabilities, better exterior durability and UV resistance, and highly resistant scratching, chipping and peeling characteristics.

AAMA specifications for the testing and evaluation of coatings use a South Florida (27° Latitude) benchmark due to its extreme weather conditions. Testing categories for AAMA 2604 acceptance include a 5-year 45° Sun Exposure, 3000 Hour Humidity Resistance, and 3000 Hour Salt Spray. AAMA 2604 powders are rated to withstand outdoor exposure for five (5) years in this worst case environment. In comparison, some competitors use AAMA 2603 coatings. AAMA 2603 products are rated for only one (1) year.

Hapco only uses AAMA 2604 powders, assuring project owners the longest lasting, lowest maintenance powder painted products available in the market today.

Hapco’s use of AAMA 2604 Powders Reduces Overall Ownership Cost By Providing Longer Lasting Aesthetics.

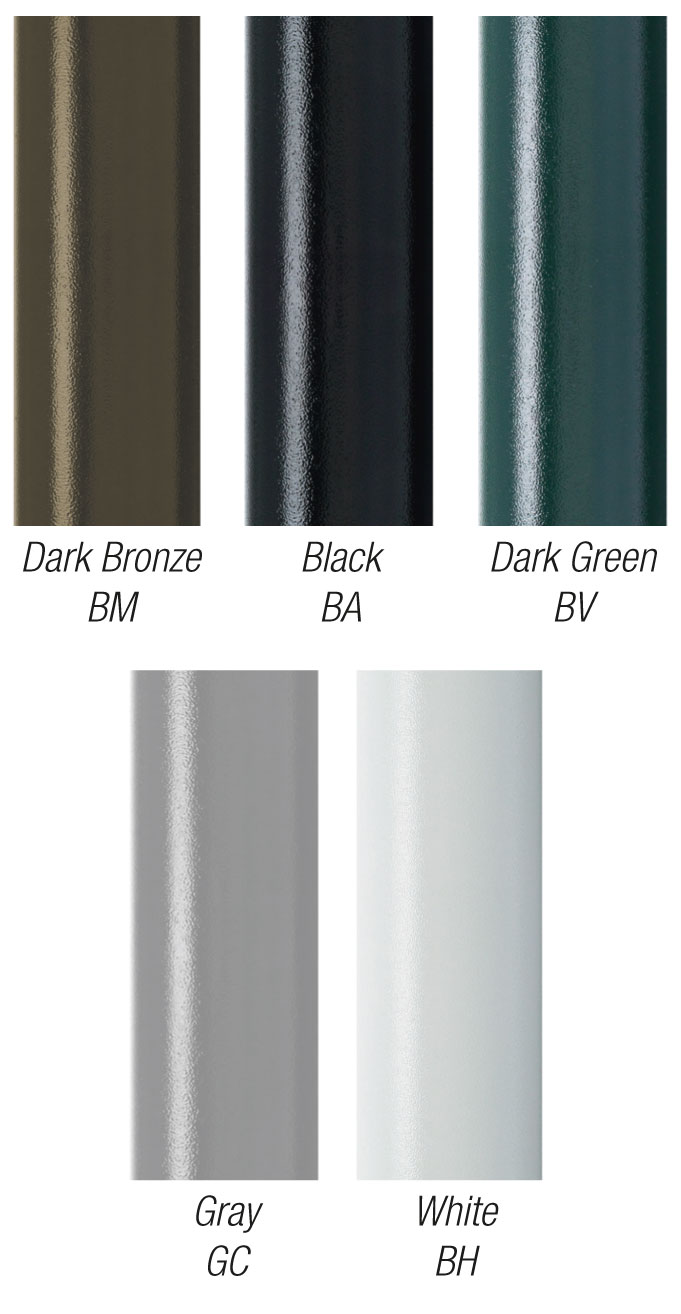

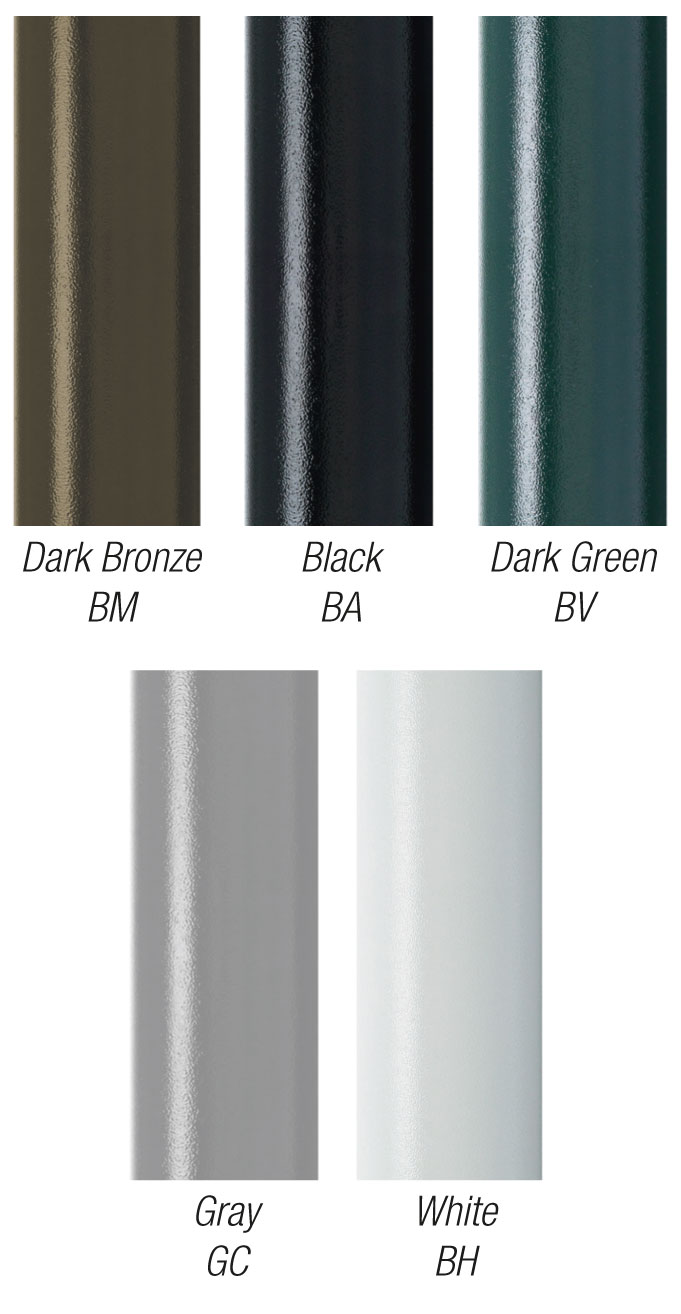

Standard Colors

Hapco standard powder coat colors are provided in a textured design for improved mar resistance.

Powder Coat finishes offer a more attractive price and lead time compared to anodized products and are recommended for guaranteed uniformity of color.

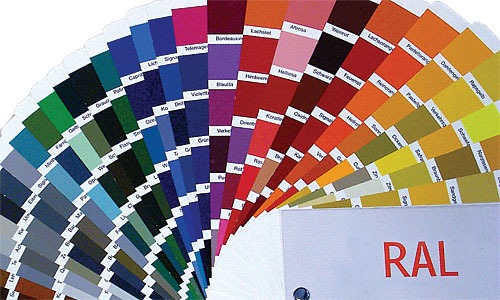

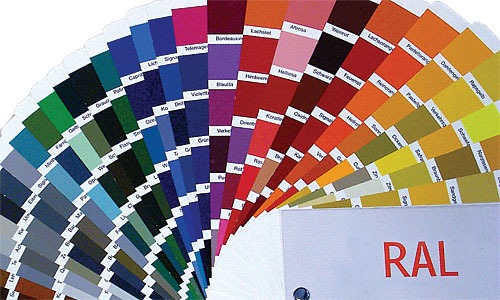

RAL and Custom Colors

Along with our standard colors, Hapco can provide both RAL and custom colors. Options are unlimited. Simply provide any RAL Color Number or Color Chip Sample and Hapco will provide the perfect AAMA 2604 Powder Paint Color for your next project.

Powder Coat – Aluminum

5-Year Finish Warranty

Hapco warrants its factory-applied powder coatings on aluminum poles against cracking, peeling or excessive fading due to normal climatic exposure for a period of five (5) years from the date of shipment. Damage to the finish coating caused by mechanical abuse, such as rough handling during installation or by vandalism, is not covered by this warranty. This warranty is limited to, at the seller’s option, the repair or replacement of the material involved and shall not include reimbursement of consequential expenses such as installation, removal of equipment, or transportation costs.

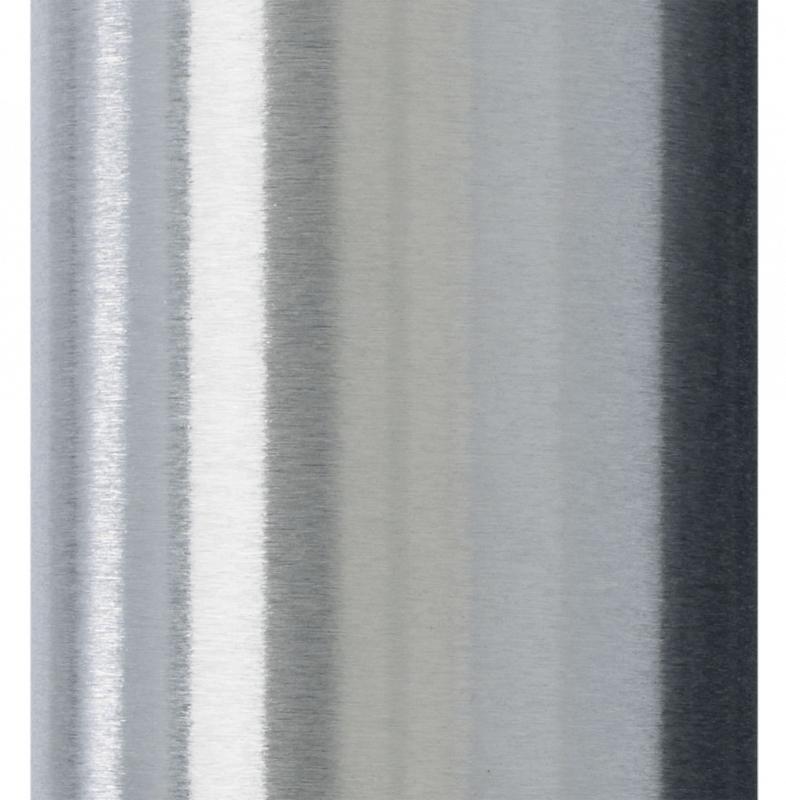

Satin Aluminum Finish

Satin Aluminum Finish

Hapco’s Satin Aluminum is a polished aluminum finish achieved in a multi-pass, mechanical rotary sanding operation. No alternative finish option offers a lower overall cost of ownership or longer aesthetic beauty, making it the industry’s first choice for low-maintenance and enduring finishes.

Hapco’s RTA and RSA round aluminum poles are constructed of Aluminum Alloy 6063. This marine grade alloy is composed primarily of Aluminum, Magnesium and Silicone and is chosen because of its superior attributes and extremely high resistance to corrosion. On contact with air, these aluminum alloys naturally oxidize, creating a layer of aluminum oxide on the surface of the pole that effectively and permanently guards against corrosion.

Smart Number Finish Codes:

- 01 – Satin Aluminum Finish – Round Poles

- 02 – Satin Aluminum Finish – Square Poles

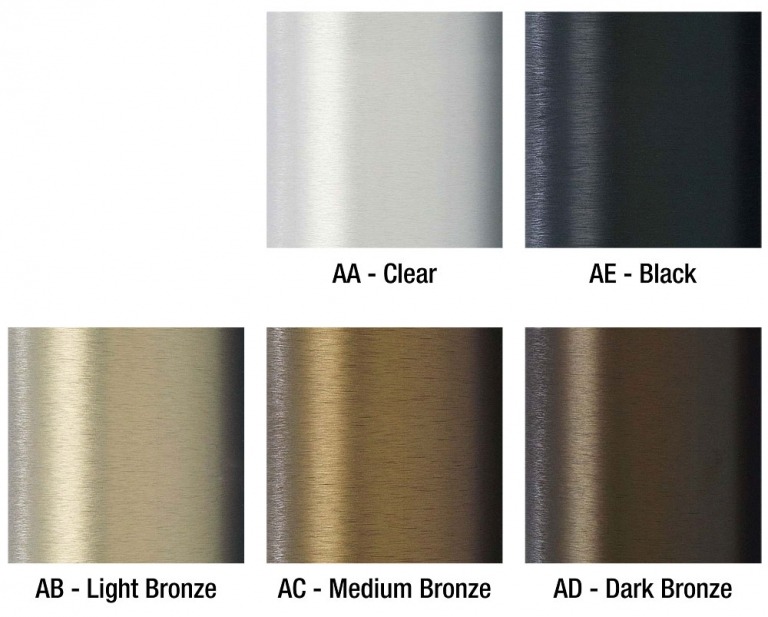

Anodized Aluminum Finish

Anodized finishes are achieved by immersing the aluminum material into an acid solution and passing a direct current through the material in such a manner as to form a durable oxide film on the surface of the pole. Anodized colors are limited to clear, black and various shades of bronze.

Color Uniformity

While a color finish on aluminum poles can be obtained by either anodizing or powder painting, anodizing of pole assemblies will inherently result in color variations and color uniformity is not guaranteed. Variations in the physical or chemical composition of the metals contained in the base flange, pole shaft, welds, and pole accessories create color variations in anodized finishes that are unavoidable. Color variations in anodized finishes are not covered under Hapco warranty.

Powder Coat finishes offer a more attractive price and lead time compared to anodized products and are recommended for guaranteed uniformity of color.

Thermoset Powder Coat Finishes – Steel

Hapco’s on-site, state-of-the-art powder coating operations utilize weather resistant triglycidyl isocyanurate (TGIC) polyester thermoset powders that are electrostatically applied, oven cured and bonded to a minimum dry film thickness of 2.0 mils. The National Association of Architectural Metal Manufacturers, Metal Finishes Manual, rate the outdoor life of these powders at 15 plus years.

AAMA 2604

All polyester thermoset powders are not created equal. The American Architectural Manufacturers Association (AAMA) provides classifications for powder coatings which are industry recognized standards for testing and performance. AAMA 2604 coatings, known as Super Durable, are formulated with advanced polyester resin technology that utilizes higher performance pigments. Qualities include superior gloss, color retention and weathering capabilities, better exterior durability and UV resistance, and highly resistant scratching, chipping and peeling characteristics.

AAMA specifications for the testing and evaluation of coatings use a South Florida (27° Latitude) benchmark due to its extreme weather conditions. Testing categories for AAMA 2604 acceptance include a 5-year 45° Sun Exposure, 3000 Hour Humidity Resistance, and 3000 Hour Salt Spray. AAMA 2604 powders are rated to withstand outdoor exposure for five (5) years in this worst case environment. In comparison, some competitors use AAMA 2603 coatings. AAMA 2603 products are rated for only one (1) year.

Hapco only uses AAMA 2604 powders, assuring project owners the longest lasting, lowest maintenance powder painted products available in the market today.

Hapco’s use of AAMA 2604 Powders Reduces Overall Ownership Cost By Providing Longer Lasting Aesthetics.

Standard Colors

Hapco standard powder coat colors are provided in a textured design for improved mar resistance.

Powder Coat finishes offer a more attractive price and lead time compared to anodized products and are recommended for guaranteed uniformity of color.

RAL and Custom Colors

Along with our standard colors, Hapco can provide both RAL and custom colors. Options are unlimited. Simply provide any RAL Color Number or Color Chip Sample and Hapco will provide the perfect AAMA 2604 Powder Paint Color for your next project.

Powder Coat – Steel

1-Year Finish Warranty

Hapco warrants its factory-applied powder coatings on steel poles against cracking, peeling or excessive fading due to normal climatic exposure for a period of one (1) years from the date of shipment. Damage to the finish coating caused by mechanical abuse, such as rough handling during installation or by vandalism, is not covered by this warranty. This warranty is limited to, at the seller’s option, the repair or replacement of the material involved and shall not include reimbursement of consequential expenses such as installation, removal of equipment, or transportation costs.

Galvanized and Powder Coat Over Galvanize

In addition to our standard Powder Coat finish, Hapco Steel poles are offered in both Galvanized and Powder Coat over Galvanized options. All galvanized steel poles are hot dip galvanized to meet ASTM-A-123 specifications.