For more than 70 years Hapco has been the nation’s leading aluminum pole producer.

Hapco achieved and maintained this position with expert engineering, manufacturing innovation, and pole product testing. We have a proud history of dedicated involvement in the research that has shaped our industry, leading to many industry patents which include the first patent on a successful pole vibration damper.

Hapco has an in-house testing facility that provides a means to test full-scale poles and brackets under static and cyclic load conditions. Thousands of tests have been conducted in the interest of product improvement. These tests, extensive research projects in collaboration with major universities, and current design specifications provide the basis for Hapco’s design criteria.

Hapco can provide designs based on the American Association of State Highway and Transportation Officials Standard Specifications for Structural Supports for Highway Signs, Luminaires and Traffic Signals (otherwise known as the AASHTO-LTS) and local building code requirements. Poles in this website are designed to meet the strength requirements of 2009 AASHTO LTS-5. Please advise Hapco of any additional requirements you may have.

Design Efficiency

Efficiency of design can lead to significant overall cost savings. In order to manage project funds efficiently, it is important to utilize materials accurately, and Hapco has the knowledge and experience to provide the most efficient offering for each pole project. There are four main factors to consider when selecting the proper pole.

1. Mounting Height: Illumination levels determine the luminaire and mounting height selection process.

2. Total Weight: The combined weight of any object that will be mounted on the pole (luminaires, arms, brackets, accessories, etc.).

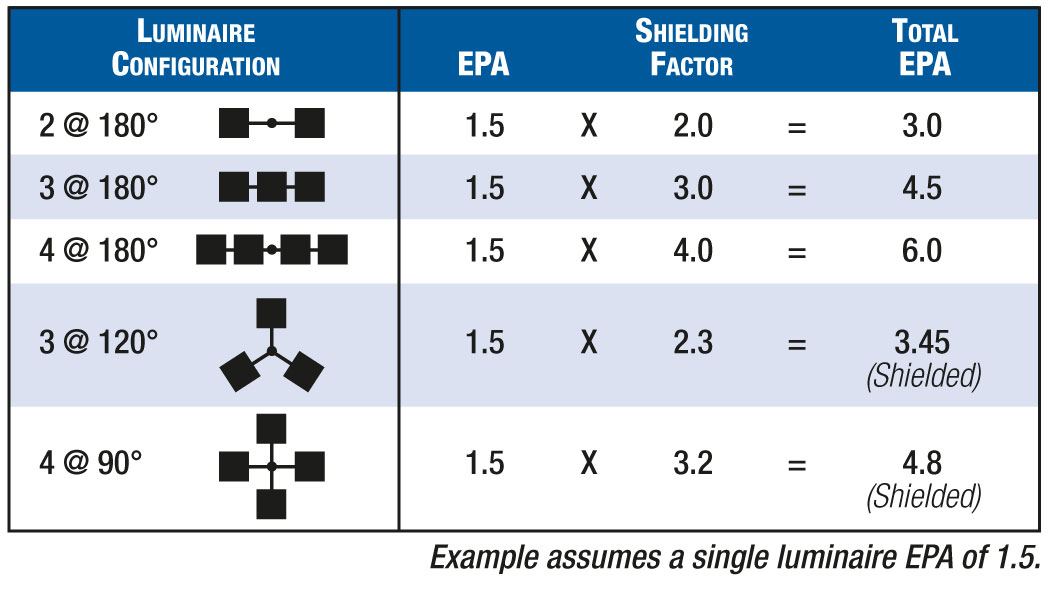

3. Total EPA: Effective Projected Area (EPA) is the product of the actual area seen by the wind multiplied by the appropriate drag coefficient and is dependent upon the angle of the wind with respect to the item being considered.

4. Wind Velocity: Location-specific, 3-second gust basic wind speed as presented in this section.

Methods of Analysis And Loading Due to Wind And Other Forces

The stresses caused by all pole attachments exist continuously throughout the life of the installation. These stresses are subject to fluctuation caused by the aerodynamics of the luminaire or other characteristics of the assembly, due to wind loads. Therefore, these stresses must be limited to a conservative value to reduce the possibility of fatigue. Other loads that should be considered are those produced by ice, overhead wiring (must be treated as a special loading challenge), and future changes to the original design. The forces anticipated in a particular installation must be known in order to select the correct pole.

Pole designs typically constitute an analysis of the combined stresses caused by the various types of loads. Our engineers evaluate each pole configuration and determine the stress that is permissible according to the design code, and the recommended loads are limited to stay within that allowable stress value.

Stiffness considerations are included in the analysis of a Hapco pole. The dead load deflection of the shaft is limited to provide an attractive appearance. The allowable deflection is based on the angular deflection, or rotation, of the shaft top, which is the characteristic that is the best measure of appearance for this type of loading.

Shielding Factor

The table shown at right will assist you in calculating the total EPA for many of the popular luminaire configurations. Using the shielding factor to calculate total EPA prevents an over-designed pole being used, resulting in cost savings.