Faster, More Cost Efficient Installations

Aluminum poles used in direct buried applications throughout the country have a 60 year record of successful installations and can provide significant overall job savings.

14 Advantages of Direct Buried Aluminum Poles

- Ease of installation

- Eliminates the need for foundations, requiring no Civil Engineer and no PE stamp, resulting in cost savings of $300 – $1000

- Eliminates the need for bolt circle templates and anchor bolts

- Speeds up the installation process while eliminating the additional freight charges of anchor bolts shipped in advance

- Eliminates the use of shims or double nuts for leveling

- Eliminates improper bolt projections that in many instances result in high and uneven base covers

- Eliminates the need, time and expense to grout

- Eliminates the possibility of foundation and anchor bolt replacement in the event of a knockdown

- Allows aluminum to be cost competitive with composite and concrete while providing a more appealing and aesthetic appearance

- Eliminates the possibility of improper pouring/setting of foundation

- Allows simple future retrofits by eliminating the need to match an existing bolt circle

- Eliminates base plate weld, providing longer fatigue life and reduced chance of failure

- Ground acts as a natural damper, reducing the risk of wind induced vibration

- Provide greater EPA values than anchor base designs by eliminating the weld joint, offering approximately 18-20% more strength which in many instances allows a one wall size reduction

Example:

Changing a 7” Dia., 25’ MH, .188” wall, anchor base design to a like pole with a .156 wall, direct buried design allows an approximate $45 price reduction (similar EPA values on both designs).

Exclusively with Hapco Aluminum

Naturally Corrosion Resistant

Hapco’s Exclusive Lifetime Warranty* guarantees against corrosion, INCLUDING Direct Buried Applications.

Looking for examples of direct buried installations in your area?

Direct Buried Aluminum flagpoles have a 60 year history of successful installations.

*Excludes installation in soils with a pH under 5 or over 9 and improper grounding.

Direct Buried Aluminum Opportunities

Reduce Cost. Improve Aesthetics. Save on your next project.

Examples of Anchor Base installations that are perfect opportunities for Hapco’s Direct Buried Aluminum Poles.

Direct Buried Pedestal Poles

Pedestal Poles are the perfect solution to the high maintenance alternative of composite poles. Utilities, Developers and Contractors can benefit from the savings associated with the highest quality, longest-lasting and lowest maintenance direct buried alternative for residential, parks and recreational applications.

FHWA Accepted Direct Buried

Hapco is proud to offer the industry’s first FHWA Accepted Direct Buried Breakaway Aluminum Pole.

Aluminum poles used in direct buried applications throughout the country have a 60 year record of successful installations and can provide significant overall job savings.

Through an extensive process of expert design, modeling, and testing, Hapco engineers have created a breakaway design that brings the cost efficient properties of direct buried poles to our FHWA accepted Breakaway product line.

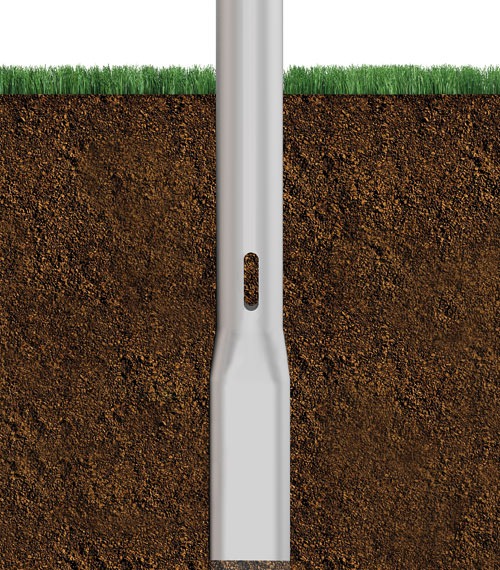

The butt end of Hapco Direct Buried Breakaway poles are partially flattened into an anti-rotational, oval cross section.

Extensively Tested

Lifetime Warranty Includes Corrosion