Direct Buried

Click image to enlarge.

To download a printable file, click PDF Download >

Details

FBC RSA Direct Buried

Catalog Pages with 2023 FBC Wind Speed Map

PDF Download >

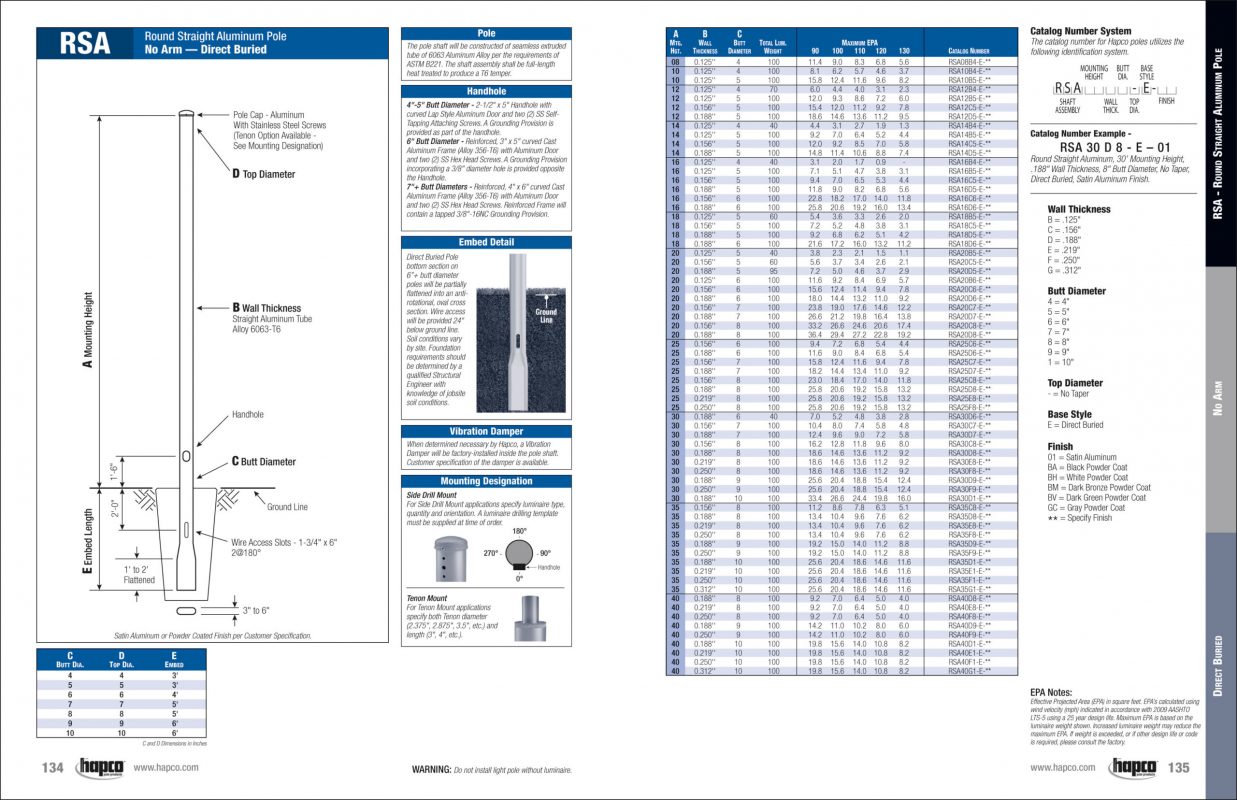

Pole

The pole shaft will be constructed of seamless extruded tube of 6063 Aluminum Alloy per the requirements of ASTM B221. The shaft assembly shall be full-length heat treated after base weld to produce a T6 temper.

Embed Detail

Direct Buried Pole bottom section on 6″+ butt diameter poles will be partially flattened into an anti-rotational, oval cross section. Wire access will be provided 24″ below ground line. Soil conditions vary by site. Foundation requirements should be determined by a qualified Structural Engineer with knowledge of jobsite soil conditions.

Handhole

4″-5″ Butt Diameters – 2″ x 4″ Handhole with curved Lap Style Aluminum Door and two (2) SS Self-Tapping Attaching Screws. A Grounding Provision incorporating a tapped 1/4″-20NC hole is provided.

6″ Butt Diameter – Reinforced, 3″ x 5″ curved Cast Aluminum Frame (Alloy 356-T6) with Aluminum Door and two (2) SS Hex Head Screws. A Grounding Provision incorporating a 3/8″ diameter hole is provided opposite the Handhole.

7″+ Butt Diameters – Reinforced, 4″ x 6″ curved Cast Aluminum Frame (Alloy 356-T6) with Aluminum Door and two (2) SS Hex Head Screws. Reinforced Frame will contain a tapped 3/8″-16NC Grounding Provision.

Vibration Damper

When determined necessary by Hapco, a Vibration Damper will be factory-installed inside the pole shaft. Customer specification of the damper is available.

Vibration Dampers

Read More >

Mounting Designation

Side Drill Mount

For Side Drill Mount applications specify luminaire type, quantity and orientation. A luminaire drilling template must be supplied at time of order.

Tenon Mount – Welded

For Tenon Mount applications specify both Tenon diameter (2.375″, 2.875″, 3.5″, etc.) and length (3″, 4″, etc.).

Satin Aluminum Finish

Pole surface will contain a uniform Brushed Aluminum natural finish. Finish to be achieved utilizing specially formulated abrasives in a multi-pass, rotary sanding operation.

Powder Coat Finish

Coating material will be a thermosetting polyester AAMA 2604 Super Durable powder electrostatically applied, oven cured and bonded in a closed loop, automated system. Minimum thickness of finish will be two (2) mils. Hapco’s Powder Coat Finish Warranty on aluminum poles is five (5) years.

Finish Options

Read More >

Pole Shaft Warranty

Hapco warrants its aluminum pole assemblies for their lifetime to be free of defects in material and workmanship.

Hapco Lifetime Pole Assembly Warranty

Read More >

Specification Drawings – RSA No Arm Direct Bury

Click on the Product No. to download interactive PDF specification drawing.